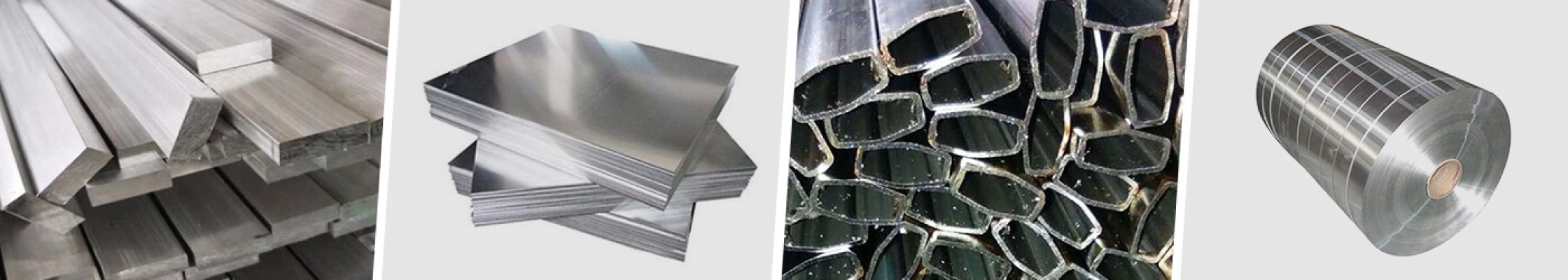

Products

Description:

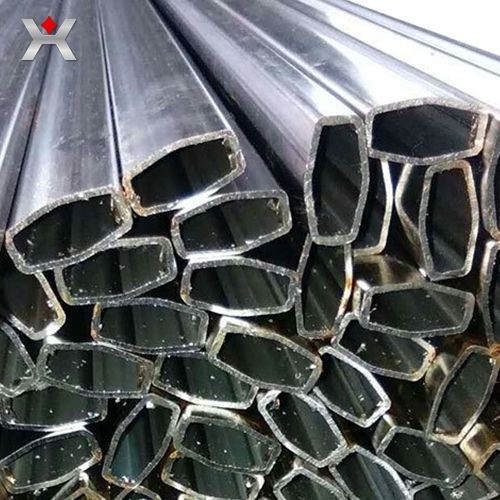

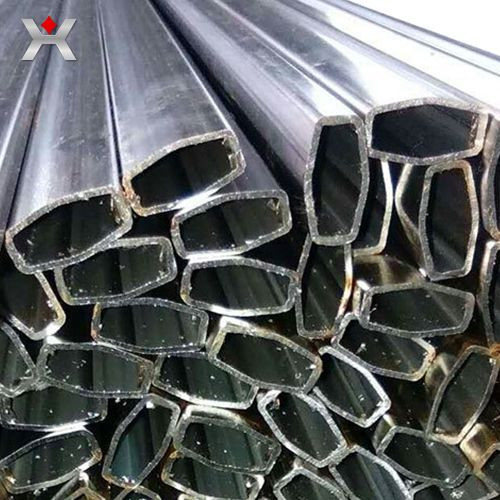

Aluminum Alloy Shaped Tube:

Aluminum alloy special-shaped tube commonly used brand 6063 is a series of aluminum - magnesium - silicon heat treatment strengthened aluminum alloy, in the al-Mg-Si composed of three elements, there are no ternary compounds, only two binary compounds Mg2Si and Mg2Al3, with α(AL)-Mg2Si pseudo-binary cross section as the boundary, formed two ternary system. The main strengthening phase of α(Al)-Mg2Si-(Si) and α(Al)-Mg2Si-Mg2Al3 in Al-Mg-Si alloys is Mg2Si. During quenching, the more Mg2Si solidly dissolved in the matrix, the higher the strength of the alloy after aging, and vice versa. In the pseudo binary phase diagram of α(Al)-Mg2Si, the eutectic temperature is 595℃, and the solubility of Mg2Si is 1.85%, which is 1.05% at 500℃. It can be seen that the temperature has a great influence on the solid solubility of Mg2Si in Al. The higher the quenching temperature is, the higher the strength after aging is; conversely, the lower the quenching temperature is. The strength decreases after aging. Some profiles produced by aluminum profile factories are qualified, but their strength is not up to the requirements. The reason is that the heating temperature of aluminum bars is not enough or hot outside and cold inside, resulting in the profile quenching temperature is too low.